Immobilization of Aspergillus fumigatus α-Amylase via Adsorption onto Bentonite/Chitosan for Stability Enhancement

Downloads

Doi:10.28991/ESJ-2023-07-05-023

Full Text:PDF

Downloads

Farooq, M. A., Ali, S., Hassan, A., Tahir, H. M., Mumtaz, S., & Mumtaz, S. (2021). Biosynthesis and industrial applications of α-amylase: a review. Archives of Microbiology, 203(4), 1281–1292. doi:10.1007/s00203-020-02128-y.

Jujjavarapu, S. E., & Dhagat, S. (2018). Evolutionary trends in industrial production of α-amylase. Recent Patents on Biotechnology, 13(1), 4–18. doi:10.2174/2211550107666180816093436.

Singh, R., Kim, S. W., Kumari, A., & Mehta, P. K. (2022). An overview of microbial α-amylase and recent biotechnological developments. Current Biotechnology, 11(1), 11–26. doi:10.2174/2211550111666220328141044.

Future Market Insights. (2022). Alpha-amylase baking enzyme market outlook (2022-2032). Future Market Insights, Newark, United States. Available online: https://www.futuremarketinsights.com/reports/alpha-amylase-baking-enzyme-market (accessed on March 2023).

Vachher, M., Sen, A., Kapila, R., & Nigam, A. (2021). Microbial therapeutic enzymes: A promising area of biopharmaceuticals. Current Research in Biotechnology, 3, 195–208. doi:10.1016/j.crbiot.2021.05.006.

Streimikyte, P., Viskelis, P., & Viskelis, J. (2022). Enzymes-assisted extraction of plants for sustainable and functional applications. International Journal of Molecular Sciences, 23(4), 2359. doi:10.3390/ijms23042359.

Barzee, T. J., Cao, L., Pan, Z., & Zhang, R. (2021). Fungi for future foods. Journal of Future Foods, 1(1), 25–37. doi:10.1016/j.jfutfo.2021.09.002.

Blaga, A. C., Caşcaval, D., & Galaction, A. I. (2022). Improved production of α-amylase by Aspergillus terreus in presence of oxygen-vector. Fermentation, 8(6), 271. doi:10.3390/fermentation8060271.

Devi, R., Revathi, K., Arunagirinathan, N., & Yogananth, N. (2022). Production and optimization of α-amylase from Aspergillus ochraceus isolated from Marakkanam Saltpans, Tamil Nadu, India. Bulletin of Environment, Pharmacology and Life Sciences, 1, 997-1002.

Premalatha, A., Vijayalakshmi, K., Shanmugavel, M., & Rajakumar, G. S. (2023). Optimization of culture conditions for enhanced production of extracellular α-amylase using solid-state and submerged fermentation from Aspergillus tamarii MTCC5152. Biotechnology and Applied Biochemistry, 70(2), 835–845. doi:10.1002/bab.2403.

Beltagy, E. A., Abouelwafa, A., & Barakat, K. M. (2022). Bioethanol production from immobilized amylase produced by marine Aspergillus flavus AUMC10636. Egyptian Journal of Aquatic Research, 48(4), 325–331. doi:10.1016/j.ejar.2022.02.003.

Sidar, A., Voshol, G. P., Vijgenboom, E., & Punt, P. J. (2023). Novel design of an α-amylase with an N-terminal CBM20 in Aspergillus niger improves binding and processing of a broad range of starches. Molecules, 28(13), 5033. doi:10.3390/molecules28135033.

Marengo, M., Pezzilli, D., Gianquinto, E., Fissore, A., Oliaro-Bosso, S., Sgorbini, B., Spyrakis, F., & Adinolfi, S. (2022). Evaluation of porcine and Aspergillus oryzae α-amylases as possible model for the human enzyme. Processes, 10(4), 780. doi:10.3390/pr10040780.

Yandri, Y., Nurmala, N., Suhartati, T., Satria, H., & Hadi, S. (2022). The stability increase of α-amylase enzyme from Aspergillus fumigatus using dimethyladipimidate. Physical Sciences Reviews, 8(10), 3655-3664. doi:10.1515/psr-2021-0138.

Fang, W., & Latgé, J.-P. (2018). Microbe profile: Aspergillus fumigatus: A saprotrophic and opportunistic fungal pathogen. Microbiology, 164(8), 1009–1011. doi:10.1099/mic.0.000651.

Rathnakumar, K., Kalaivendan, R. G. T., Eazhumalai, G., Raja Charles, A. P., Verma, P., Rustagi, S., Bharti, S., Kothakota, A., Siddiqui, S. A., Manuel Lorenzo, J., & Pandiselvam, R. (2023). Applications of ultrasonication on food enzyme inactivation- recent review report (2017–2022). Ultrasonics Sonochemistry, 96, 106407. doi:10.1016/j.ultsonch.2023.106407.

Mohamad, N. R., Marzuki, N. H. C., Buang, N. A., Huyop, F., & Wahab, R. A. (2015). An overview of technologies for immobilization of enzymes and surface analysis techniques for immobilized enzymes. Biotechnology & Biotechnological Equipment, 29(2), 205–220. doi:10.1080/13102818.2015.1008192.

Zhang, Y., Ge, J., & Liu, Z. (2015). Enhanced activity of immobilized or chemically modified enzymes. ACS Catalysis, 5(8), 4503–4513. doi:10.1021/acscatal.5b00996.

Oliveira, F. L., de S. França, A., de Castro, A. M., Alves de Souza, R. O. M., Esteves, P. M., & Gonçalves, R. S. B. (2020). Enzyme immobilization in covalent organic frameworks: Strategies and applications in biocatalysis. ChemPlusChem, 85(9), 2051–2066. doi:10.1002/cplu.202000549.

Zdarta, J., Meyer, A. S., Jesionowski, T., & Pinelo, M. (2018). A general overview of support materials for enzyme immobilization: Characteristics, properties, practical utility. Catalysts, 8(2), 92. doi:10.3390/catal8020092.

Dong, H., Li, Y., Li, J., Sheng, G., & Chen, H. (2013). Comparative study on lipases immobilized onto bentonite and modified bentonites and their catalytic properties. Industrial & Engineering Chemistry Research, 52(26), 9030–9037. doi:10.1021/ie4001986.

Mo, H., & Qiu, J. (2020). Preparation of chitosan/magnetic porous biochar as support for cellulase immobilization by using glutaraldehyde. Polymers, 12(11), 2672. doi:10.3390/polym12112672.

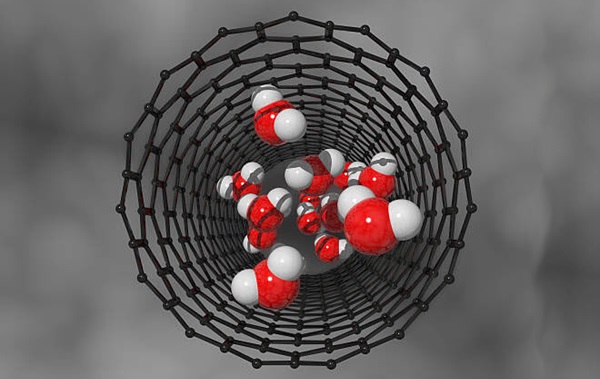

Tiarsa, E. R., Yandri, Y., Suhartati, T., Satria, H., Irawan, B., & Hadi, S. (2022). The stability improvement of Aspergillus fumigatus α-amylase by immobilization onto chitin-bentonite hybrid. Biochemistry Research International, 2022, 5692438. doi:10.1155/2022/5692438.

Yandri, Y., Tiarsa, E. R., Suhartati, T., Satria, H., Irawan, B., & Hadi, S. (2022). The stability improvement of α-amylase enzyme from Aspergillus fumigatus by immobilization on a bentonite matrix. Biochemistry Research International, 2022, 3797629. doi:10.1155/2022/3797629.

Yandri, Y., Ropingi, H., Suhartati, T., Hendri, J., Irawan, B., & Hadi, S. (2022). The effect of zeolite/chitosan hybrid matrix for thermal-stabilization enhancement on the immobilization of Aspergillus fumigatus α-amylase. Emerging Science Journal, 6(3), 505–518. doi:10.28991/ESJ-2022-06-03-06.

Bollag, D. M., Rozycki, M. D., & Edelstein, S. J. (1996). Protein methods (2nd Ed.). John Wiley & Sons, Hoboken, United States.

Fuwa, H. (1954). A new method for microdetermination of amylase activity by the use of amylose as the substrate. Journal of Biochemistry, 41(5), 583–603. doi:10.1093/oxfordjournals.jbchem.a126476.

Eveleigh, D. E., Mandels, M., Andreotti, R., & Roche, C. (2009). Measurement of saccharifying cellulase. Biotechnology for Biofuels, 2(1), 21. doi:10.1186/1754-6834-2-21.

Lowry, O. H., Rosebrough, N. J., Farr, A. L., & Randall, R. J. (1951). Protein measurement with the Folin phenol reagent. The Journal of Biological Chemistry, 193(1), 265–275. doi:10.1016/s0021-9258(19)52451-6.

Yang, Z., Domach, M., Auger, R., Yang, F. X., & Russell, A. J. (1996). Polyethylene glycol-induced stabilization of subtilisin. Enzyme and Microbial Technology, 18(2), 82–89. doi:10.1016/0141-0229(95)00073-9.

Kazan, D., Ertan, H., & Erarslan, A. (1997). Stabilization of Escherichia coli penicillin G acylase against thermal inactivation by cross-linking with dextran dialdehyde polymers. Applied Microbiology and Biotechnology, 48(2), 191–197. doi:10.1007/s002530051037.

Planchot, V., & Colonna, P. (1995). Purification and characterization of extracellular alpha-amylase from Aspergillus fumigatus. Carbohydrate Research, 272(1), 97–109. doi:10.1016/0008-6215(95)00035-R.

Ahmed, K., Valeem, E. E., Khan, M. A., & Qamar-Ul-Haq. (2015). Biosynthesis of alpha amylase from Aspergillus fumigatus (fresenius 1863) in submerged fermentation. Pakistan Journal of Biotechnology, 12(2), 89–92.

Akhter, M., Hossain, M. T., & Anwar, M. (2013). Factors responsible for production of amylases from Aspergillus fumigatus Fresenius. Chittagong University Journal of Biological Sciences, 11–20. doi:10.3329/cujbs.v3i1.13402.

Chen, Y., Huang, R., Zhu, C., Wu, D., Sun, Y., He, Y., & Ye, W. (2014). Adsorptive removal of La(III) from aqueous solutions with 8-hydroxyquinoline immobilized GMZ bentonite. Journal of Radioanalytical and Nuclear Chemistry, 299(1), 665–674. doi:10.1007/s10967-013-2768-4.

Chen, X., Wang, J., Wang, S., Ma, F., Chen, X., & Li, J. (2015). Effect of solution properties on the interaction of 90Sr(II) with GMZ bentonite. Korean Journal of Chemical Engineering, 32(11), 2264–2272. doi:10.1007/s11814-015-0045-7.

Belousov, P., Semenkova, A., Egorova, T., Romanchuk, A., Zakusin, S., Dorzhieva, O., Tyupina, E., Izosimova, Y., Tolpeshta, I., Chernov, M., & Krupskaya, V. (2019). Cesium sorption and desorption on glauconite, bentonite, zeolite, and diatomite. Minerals, 9(10), 625. doi:10.3390/min9100625.

Tabak, A., Afsin, B., Caglar, B., & Koksal, E. (2007). Characterization and pillaring of a Turkish bentonite (Resadiye). Journal of Colloid and Interface Science, 313(1), 5–11. doi:10.1016/j.jcis.2007.02.086.

Zvezdova, D. (2010). Synthesis and characterization of chitosan from marine sources in Black Sea. Annual Proceedings,"Angel Kanchev" University of Ruse, 49(9.1), 65-69.

Chen, C., Gao, Z., Qiu, X., & Hu, S. (2013). Enhancement of the controlled-release properties of chitosan membranes by crosslinking with suberoyl chloride. Molecules, 18(6), 7239–7252. doi:10.3390/molecules18067239.

Augustine, M., Madhusudhanan, D. T., & Velayudhan, M. P. (2023). Thermal deactivation studies of alpha-amylase immobilized onto core-shell structured aniline formaldehyde crosslinked polyaniline magnetic nanocomposite. Biotechnology & Biotechnological Equipment, 37(1), 273–285. doi:10.1080/13102818.2023.2182150.

Wang, Z., Ren, D., Cheng, Y., Zhang, X., Zhang, S., & Chen, W. (2022). Immobilization of laccase on chitosan functionalized halloysite nanotubes for degradation of Bisphenol A in aqueous solution: Degradation mechanism and mineralization pathway. Heliyon, 8(7), 9919. doi:10.1016/j.heliyon.2022.e09919.

Madera-Santana, T. J., Herrera-Méndez, C. H., & Rodríguez-Núñez, J. R. (2018). An overview of the chemical modifications of chitosan and their advantages. Green Materials, 6(4), 131–142. doi:10.1680/jgrma.18.00053.

Alnadari, F., Xue, Y., Zhou, L., Hamed, Y. S., Taha, M., & Foda, M. F. (2020). Immobilization of β-glucosidase from Thermatoga maritima on chitin-functionalized magnetic nanoparticle via a novel thermostable chitin-binding domain. Scientific Reports, 10(1), 1–12. doi:10.1038/s41598-019-57165-5.

Yandri, Y., Tiarsa, E. R., Suhartati, T., Irawan, B., & Hadi, S. (2023). Immobilization and stabilization of Aspergillus fumigatus α-amylase by adsorption on a chitin. Emerging Science Journal, 7(1), 77–89. doi:10.28991/ESJ-2023-07-01-06.

Klapiszewski, Š., Zdarta, J., & Jesionowski, T. (2018). Titania/lignin hybrid materials as a novel support for α-amylase immobilization: A comprehensive study. Colloids and Surfaces B: Biointerfaces, 162, 90–97. doi:10.1016/j.colsurfb.2017.11.045.

Bodakowska-Boczniewicz, J., & Garncarek, Z. (2019). Immobilization of naringinase from penicillium decumbens on chitosan microspheres for debittering grapefruit juice. Molecules, 24(23), 4234. doi:10.3390/molecules24234234.

Tincu, C. E., Bouhadiba, B., Atanase, L. I., Stan, C. S., Popa, M., & Ochiuz, L. (2023). An accessible method to improve the stability and reusability of porcine pancreatic α-amylase via immobilization in gellan-based hydrogel particles obtained by ionic cross-linking with Mg2+ ions. Molecules, 28(12), 4695. doi:10.3390/molecules28124695.

Ahmed, N. E., El Shamy, A. R., & Awad, H. M. (2020). Optimization and immobilization of amylase produced by Aspergillus terreus using pomegranate peel waste. Bulletin of the National Research Centre, 44(1), 109. doi:10.1186/s42269-020-00363-3.

Yandri, Y., Ropingi, H., Suhartati, T., Irawan, B., & Hadi, S. (2023). Immobilization of α-amylase from Aspergillus fumigatus using adsorption method onto zeolite. Physical Sciences Reviews, 1-12. doi:10.1515/psr-2022-0258.

Nazarova, E. A., Yushkova, E. D., Ivanets, A. I., Prozorovich, V. G., Krivoshapkin, P. V., & Krivoshapkina, E. F. (2021). α-Amylase immobilization on ceramic membranes for starch hydrolysis. Starch - Stärke, 74(1), 1-9. doi:10.1002/star.202100017.

Kaushal, J., Seema, Singh, G., & Arya, S. K. (2018). Immobilization of catalase onto chitosan and chitosan–bentonite complex: A comparative study. Biotechnology Reports, 18, 258. doi:10.1016/j.btre.2018.e00258.

Califano, V., & Costantini, A. (2020). Immobilization of cellulolytic enzymes in mesostructured silica materials. Catalysts, 10(6), 706. doi:10.3390/catal10060706.

Zhang, H., Nie, M., Gu, Z., Xin, Y., Zhang, L., Li, Y., & Shi, G. (2023). Preparation of water-insoluble lignin nanoparticles by deep eutectic solvent and its application as a versatile and biocompatible support for the immobilization of α-amylase. International Journal of Biological Macromolecules, 249, 125975. doi:10.1016/j.ijbiomac.2023.125975.

Yandri, Y., Suhartati, T., Satria, H., Widyasmara, A., & Hadi, S. (2020). Increasing stability of α-amylase obtained from Bacillus subtilis ITBCCB148 by immobilization with chitosan. Mediterranean Journal of Chemistry, 10(2), 155–161. doi:10.13171/mjc10202002131126ysh.

Wu, L., Wu, S., Xu, Z., Qiu, Y., Li, S., & Xu, H. (2016). Modified nanoporous titanium dioxide as a novel carrier for enzyme immobilization. Biosensors and Bioelectronics, 80, 59–66. doi:10.1016/j.bios.2016.01.045.

Dhiman, S., Srivastava, B., Singh, G., Khatri, M., & Arya, S. K. (2020). Immobilization of manganese on sodium alginate-grafted-β-cyclodextrin: An easy and cost effective approach for the improvement of enzyme properties. International Journal of Biological Macromolecules, 156, 1347–1358. doi:10.1016/j.ijbiomac.2019.11.175.

Yandri, Susanti, D., Suhartati, T., & Hadi, S. (2012). Immobilization of α-amylase from locale bacteria isolate Bacillus subtilis ITBCCB148 with carboxymethyl cellulose (CM-Cellulose). Modern Applied Science, 6(3), 81–86. doi:10.5539/mas.v6n3p81.

Muhammad Firdaus Kumar, N. K., Meng, C. C., Manas, N. H. A., Ahmad, R. A., Mohd Fuzi, S. F. Z., Rahman, R. A., & Md Illias, R. (2022). Immobilization of maltogenic amylase in alginate-chitosan beads for improved enzyme retention and stability. Malaysian Journal of Fundamental and Applied Sciences, 18(1), 43–51. doi:10.11113/MJFAS.V18N1.2381.

- This work (including HTML and PDF Files) is licensed under a Creative Commons Attribution 4.0 International License.