Cellulose Microfiber Encapsulated Probiotic: Viability, Acid and Bile Tolerance during Storage at Different Temperature

Downloads

Doi:10.28991/ESJ-2022-06-01-08

Full Text:PDF

Downloads

Abdullah, N., & Sulaim, F. (2013). The Oil Palm Wastes in Malaysia. Biomass Now - Sustainable Growth and Use. doi:10.5772/55302.

Anonymous. Indonesian Palm Oil Data and Facts: Areas, Distribution and Challenges Webinars; 2020; Ngopini Palm #2 Indonesian Palm Oil Show.

Rosli, F., Ghazali, C. M. R., Al Bakri Abdullah, M. M., & Hussin, K. (2016). A Review: Characteristics of Oil Palm Trunk (OPT) and quality improvement of palm trunk plywood by resin impregnation. BioResources, 11(2), 5565–5580. doi:10.15376/BIORES.11.2.5565-5580.

Abdul Khalil, H. P. S., Nurul Fazita, M. R., Bhat, A. H., Jawaid, M., & Nik Fuad, N. A. (2010). Development and material properties of new hybrid plywood from oil palm biomass. Materials and Design, 31(1), 417–424. doi:10.1016/j.matdes.2009.05.040.

Dungani, R., Jawaid, M., Khalil, H. A., Jasni, J., Aprilia, S., Hakeem, K. R., ... & Islam, M. N. (2013). A review on quality enhancement of oil palm trunk waste by resin impregnation: Future materials. BioResources, 8(2), 3136-3156.

Belgacem, C., Serra-Parareda, F., Tarrés, Q., Mutjé, P., Delgado-Aguilar, M., & Boufi, S. (2021). The integral utilization of date palm waste to produce plastic composites. Polymers, 13(14), 2335. doi:10.3390/polym13142335.

Akmar, P. F., & Kennedy, J. F. (2001). The potential of oil and sago palm trunk wastes as carbohydrate resources. Wood Science and Technology, 35(5), 467–473. doi:10.1007/s002260100107.

Cahyaningtyas, A. A., Ermawati, R., Supeni, G., Firda, A., Masruchin, N., Kusumaningrum, W. B., Pramasari, D. A., Darmawan, T., Wibowo, E. S., Triwibowo, D., Sukma, S., Gatot, J., Kav, S., Selatan, J., Khusus, D., & Jakarta, I. (2019). Modification and Characterization of Oil Palm Trunks Starch by Hydrolysis as Bioplastic Raw Material. Jurnal Kimia Dan Kemasan, 41(1), 37–44.

Marlida, Y., Arnim, & Roza, E. (2016). The effect treated of oil palm trunk by ligninase thermostable to improvement fiber quality as energy sources by ruminant. International Journal of ChemTech Research, 9(9), 429–436.

Utara, S. Morphology of microfibrillated cellulose from primary sludge. Jurnal Ilmu Teknologi Kayu Tropis, 177–183.

Fahma, F., Iwamoto, S., Hori, N., Iwata, T., & Takemura, A. (2010). Isolation, preparation, and characterization of nanofibers from oil palm empty-fruit-bunch (OPEFB). Cellulose, 17(5), 977–985. doi:10.1007/s10570-010-9436-4.

Chinga-Carrasco, G. (2011). Cellulose fibres, nanofibrils and microfibrils: The morphological sequence of MFC components from a plant physiology and fibre technology point of view. Nanoscale Research Letters, 6(1), 1–7. doi:10.1186/1556-276X-6-417.

Lavoine, N., Desloges, I., Dufresne, A., & Bras, J. (2012). Microfibrillated cellulose - Its barrier properties and applications in cellulosic materials: A review. Carbohydrate Polymers, 90(2), 735–764. doi:10.1016/j.carbpol.2012.05.026.

Kechagia, M., Basoulis, D., Konstantopoulou, S., Dimitriadi, D., Gyftopoulou, K., Skarmoutsou, N., & Fakiri, E. M. (2013). Health Benefits of Probiotics: A Review. ISRN Nutrition, 2013, 1–7. doi:10.5402/2013/481651.

Abbasiliasi, S., Tan, J. S., Tengku Ibrahim, T. A., Bashokouh, F., Ramakrishnan, N. R., Mustafa, S., & Ariff, A. B. (2017). Fermentation factors influencing the production of bacteriocins by lactic acid bacteria: A review. RSC Advances, 7(47), 29395–29420. doi:10.1039/c6ra24579j.

Sarvari, F., Mortazavian, A. M., & Fazeli, M. R. (2014). Biochemical characteristics and viability of probiotic and yogurt bacteria in yogurt during the fermentation and refrigerated storage. Applied Food Biotechnology, 1(1), 55–61. doi:10.22037/afb.v1i1.7125.

Hu, S., Wang, L., & Jiang, Z. (2017). Dietary Additive Probiotics Modulation of the Intestinal Microbiota. Protein & Peptide Letters, 24(5), 382–387. doi:10.2174/0929866524666170223143615.

Hegazi, A. G. (2019). 2020 Market Analysis for Microbiome, Probiotics & Gut Nutrition. 2nd International Conference on Microbiome, Probiotics & Gut Nutrition, 3(1), 2020.

Min, M., Bunt, C. R., Mason, S. L., & Hussain, M. A. (2019). Non-dairy probiotic food products: An emerging group of functional foods. Critical Reviews in Food Science and Nutrition, 59(16), 2626–2641. doi:10.1080/10408398.2018.1462760.

Rodrigues, F. J., Cedran, M. F., Bicas, J. L., & Sato, H. H. (2020). Encapsulated probiotic cells: Relevant techniques, natural sources as encapsulating materials and food applications – A narrative review. Food Research International, 137, 109682. doi:10.1016/j.foodres.2020.109682.

Anjum Ayoub, Monika Sood, Jagmohan Singh, Julie D Bandral, N. G. and A. B. (2019). Microencapsulation and its applications in food industry. Journal of Pharmacognosy and Phytochemistry, 8(3), 32–37. https://dergipark.org.tr/tr/pub/pajes/218308

de la Cruz Pech-Canul, A., Ortega, D., García-Triana, A., González-Silva, N., & Solis-Oviedo, R. L. (2020). A brief review of edible coating materials for the microencapsulation of probiotics. Coatings, 10(3), 1–34. doi:10.3390/coatings10030197.

Abghari, A., Sheikh-Zeinoddin, M., & Soleimanian-Zad, S. (2011). Nonfermented ice cream as a carrier for Lactobacillus acidophilus and Lactobacillus rhamnosus. International Journal of Food Science and Technology, 46(1), 84–92. doi:10.1111/j.1365-2621.2010.02453.x.

Tripathi, M. K., & Giri, S. K. (2014). Probiotic functional foods: Survival of probiotics during processing and storage. Journal of Functional Foods, 9(1), 225–241. doi:10.1016/j.jff.2014.04.030.

Rathore, S., Desai, P. M., Liew, C. V., Chan, L. W., & Heng, P. W. S. (2013). Microencapsulation of microbial cells. Journal of Food Engineering, 116(2), 369–381. doi:10.1016/j.jfoodeng.2012.12.022.

Gasperini, L., Mano, J. F., & Reis, R. L. (2014). Natural polymers for the microencapsulation of cells. Journal of the Royal Society Interface, 11(100). doi:10.1098/rsif.2014.0817.

Chen, J., Wang, Q., Liu, C. M., & Gong, J. (2017). Issues deserve attention in encapsulating probiotics: Critical review of existing literature. Critical Reviews in Food Science and Nutrition, 57(6), 1228–1238. doi:10.1080/10408398.2014.977991.

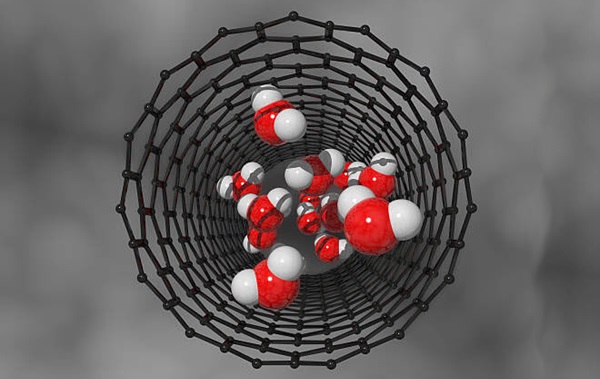

Pato, U., Ayu, D. F., Riftyan, E., Restuhadi, F., Pawenang, W. T., Firdaus, R., Rahma, A., Surono, I. S., & Jaswir, I. (2021). Physicochemical property of oil palm leaves and utilization of cellulose microfiber as probiotic encapsulant. Biodiversitas, 22(7), 2937–2944. doi:10.13057/biodiv/d220746.

Books in Brief. (1997). Journal of AOAC INTERNATIONAL, 80(6), 127A–128A. doi:10.1093/jaoac/80.6.127a.

Jung, S. J., Kim, S. H., & Chung, I. M. (2015). Comparison of lignin, cellulose, and hemicellulose contents for biofuels utilization among 4 types of lignocellulosic crops. Biomass and Bioenergy, 83, 322–327. doi:10.1016/j.biombioe.2015.10.007.

Yasim-Anuar, T. A. T., Ariffin, H., Norrrahim, M. N. F., & Hassan, M. A. (2017). Factors affecting spinnability of oil palm mesocarp fiber cellulose solution for the production of microfiber. BioResources, 12(1), 715–734. doi:10.15376/biores.12.1.715-734.

Lestari, F. A., (2016). Production of cellulose nanofiber hydrogels from oil palm empty fruit bunches. Thesis. Bogor Agricultural University, Bogor, Indonesia.

Fung, W. Y., Yuen, K. H., & Liong, M. T. (2011). Agrowaste-based nanofibers as a probiotic encapsulant: Fabrication and characterization. Journal of Agricultural and Food Chemistry, 59(15), 8140–8147. doi:10.1021/jf2009342.

Yasim-Anuar, T. A. T., Ariffin, H., & Hassan, M. A. (2018). Characterization of cellulose nanofiber from oil palm mesocarp fiber produced by ultrasonication. IOP Conference Series: Materials Science and Engineering, 368(1). doi:10.1088/1757-899X/368/1/012033.

Pato, U., Ali, M., & Parlindungan, A. K. (2005). Taurocholate deconjugation and cholesterol binding by indigenous dadih lactic acid bacteria. HAYATI Journal of Biosciences, 12(3), 103–107. doi:10.1016/S1978-3019(16)30334-5.

Nuraida, L., S, S., Palupi, N. S., H, H., Bastomi, R. R., Priscilia, D., & Nurjanah, S. (2012). Evaluation of probiotics properties of lactic acid bacteria isolated from breast milk and their potency as starter culture for yoghurt fermentation. International Journal of Food, Nutrition and Public Health, 5(1-2–3), 33–60. doi:10.47556/j.ijfnph.5.1-2-3.2012.3.

IBM SPSS Statistics 26 [Computer software]. Available online: https://www.ibm.com/support/pages/downloading-ibm-spss-statistics-26 (accessed on August 2021).

Ridwansyah, M. Z., Nasution, T. C., Sunarti, & Fauzi, A. M. Physico-chemical characteristics of oil palm starter. Jurnal Teknologi Industri Pertanian, 17(1), 1–6,

Winarni, I., Komarayati, S., & Bardant, T. B. (2016). Enzymatic Production of Bioethanol from Palm Oil Trunk Waste (Elaeis Guineensis) with the Addition of Surfactants. Jurnal Penelitian Hasil Hutan, 34(2), 127–135. doi:10.20886/jphh.2016.34.2.127-135.

Lamaming, J., Chai Chew, S., Hashim, R., Sulaiman, O., & Sugimoto, T. (2017). Extraction of microcrystalline cellulose from oil palm trunk. Journal of the Japan Institute of Energy, 96(11), 513–518. doi:10.3775/jie.96.513.

Tomimura, Y. (1992). Chemical characteristics and utilization of oil palm trunks. Jarq-Japan Agricultural Research Quarterly, 25(4), 283–288.

Deli, N. A. (2017). Delignification of nonproductive palm trunk by organosolv process with formic acid. Industria: Jurnal Teknologi Dan Manajemen Agroindustri, 6(3), 113–118. doi:10.21776/ub.industria.2017.006.03.1.

Lamaming, J., Chai Chew, S., Hashim, R., Sulaiman, O., & Sugimoto, T. (2017). Extraction of Microcrystalline Cellulose from Oil Palm Trunk. Journal of the Japan Institute of Energy, 96(11), 513–518. doi:10.3775/jie.96.513.

Gümüskaya, E., Usta, M., & Kirci, H. (2003). The effects of various pulping conditions on crystalline structure of cellulose in cotton linters. Polymer Degradation and Stability, 81(3), 559–564. doi:10.1016/S0141-3910(03)00157-5.

Chen, L., Wang, Q., Hirth, K., Baez, C., Agarwal, U. P., & Zhu, J. Y. (2015). Tailoring the yield and characteristics of wood cellulose nanocrystals (CNC) using concentrated acid hydrolysis. Cellulose, 22(3), 1753–1762. doi:10.1007/s10570-015-0615-1.

Sun, R. C., Tomkinson, J., Ma, P. L., & Liang, S. F. (2000). Comparative study of hemicelluloses from rice straw by alkali and hydrogen peroxide treatments. Carbohydrate Polymers, 42(2), 111–122. doi:10.1016/S0144-8617(99)00136-8.

Sianturi, A.H., (2018). Analysis of total hardness and alkalinity in clean water drilling wells with the Titrim method in Sucofindo, Co. Thesis. Universitas Sumatera Utara, Nort Sumatera, Indonesia.

Bilang, M., Tahir, M., & Haedar, D. (2018). Studying the encapsulation viability of probiotic cells (Lactobacillus plantarum and Streptococcus thermophilus) in ice cream. Canrea Journal: Food Technology, Nutritions, and Culinary Journal, 41–52. doi:10.20956/canrea.v1i1.21.

Hossain, M. N., Ranadheera, C. S., Fang, Z., & Ajlouni, S. (2021). Impact of encapsulating probiotics with cocoa powder on the viability of probiotics during chocolate processing, storage, and in vitro gastrointestinal digestion. Journal of Food Science, 86(5), 1629–1641. doi:10.1111/1750-3841.15695.

Massounga Bora, A. F., Li, X., Zhu, Y., & Du, L. (2019). Improved viability of microencapsulated probiotics in a freeze-dried banana powder during storage and under simulated gastrointestinal tract. probiotics and antimicrobial proteins, 11(4), 1330–1339. doi:10.1007/s12602-018-9464-1.

Arepally, D., Reddy, R. S., & Goswami, T. K. (2020). Studies on survivability, storage stability of encapsulated spray dried probiotic powder. Current Research in Food Science, 3, 235–242. doi:10.1016/j.crfs.2020.09.001.

Hill, C., Guarner, F., Reid, G., Gibson, G. R., Merenstein, D. J., Pot, B., Morelli, L., Canani, R. B., Flint, H. J., Salminen, S., Calder, P. C., & Sanders, M. E. (2014). Expert consensus document: The international scientific association for probiotics and prebiotics consensus statement on the scope and appropriate use of the term probiotic. Nature Reviews Gastroenterology and Hepatology, 11(8), 506–514. doi:10.1038/nrgastro.2014.66.

Rizqiati, H., Nurhidayat, N., & Nurwitri, C. C. Characteristics of probiotic microcapsules of Lactobacillus plantarum encapsulated with skim milk and arabic gums. J. Indon. Trop. Anim. Agric, 34(2), 139–144.

Ngov, Sina; Sukboonyasatit, Duljira; Phaseepol, T. (2014). Enhancement of probiotic survival in low pH and bile salt condition using alginate-hi-maize starch encapsulation. KKU Res. J., 19, 141–147.

Afzaal, M., Saeed, F., Arshad, M. U., Nadeem, M. T., Saeed, M., & Tufail, T. (2019). The effect of encapsulation on the stability of probiotic bacteria in ice cream and simulated gastrointestinal conditions. Probiotics and Antimicrobial Proteins, 11(4), 1348–1354. doi:10.1007/s12602-018-9485-9.

Sohail, A., Turner, M. S., Coombes, A., Bostrom, T., & Bhandari, B. (2011). Survivability of probiotics encapsulated in alginate gel microbeads using a novel impinging aerosols method. International Journal of Food Microbiology, 145(1), 162–168. doi:10.1016/j.ijfoodmicro.2010.12.007.

De Smet, I., Van Hoorde, L., Vande Woestyne, M., Christiaens, H., & Verstraete, W. (1995). Significance of bile salt hydrolytic activities of lactobacilli. Journal of Applied Bacteriology, 79(3), 292–301. doi:10.1111/j.1365-2672.1995.tb03140.x.

Dianawati, D., Mishra, V., & Shah, N. P. (2016). Viability, acid and bile tolerance of spray dried probiotic bacteria and some commercial probiotic supplement products kept at room temperature. Journal of Food Science, 81(6), M1472–M1479. doi:10.1111/1750-3841.13313.

Dikit, P., H-Kittikun, A., & Maneerat, S. (2015). Survival of encapsulated potentially probiotic Lactobacillus plantarum D6SM3 with bioemulsifier derived from spent yeast in simulated gastrointestinal conditions. Songklanakarin Journal of Science and Technology, 37(4), 425–432.

Ding, W. K., & Shah, N. P. (2007). Acid, bile, and heat tolerance of free and microencapsulated probiotic bacteria. Journal of Food Science, 72(9), 446–450. doi:10.1111/j.1750-3841.2007.00565.x.

Usman, & Hosono, A. (1999). Viability of Lactobacillus gasseri and its cholesterol-binding and antimutagenic activities during subsequent refrigerated storage in nonfermented milk. Journal of Dairy Science, 82(12), 2536–2542. doi:10.3168/jds.S0022-0302(99)75507-4.

Praepanitchai, O. A., Noomhorm, A., Anal, A. K., & Potes, M. E. (2019). Survival and behavior of encapsulated probiotics (Lactobacillus plantarum) in calcium-alginate-soy protein isolate-based hydrogel beads in different processing conditions (pH and temperature) and in pasteurized mango juice. BioMed Research International, 2019(3). doi:10.1155/2019/9768152.

- This work (including HTML and PDF Files) is licensed under a Creative Commons Attribution 4.0 International License.